At Atlanta Stretch we always work on site so that we can adapt all our machinery to each client. In today’s success story, we visit the warehouses of a manufacturer with a special need: wrapping lightweight packages. We are presented with the need to carry out a very particular project, adapted practically to the millimetre. No sooner said than done, here’s the solution that the engineering team came up with for them.

Production: More than 50 pallets/hora

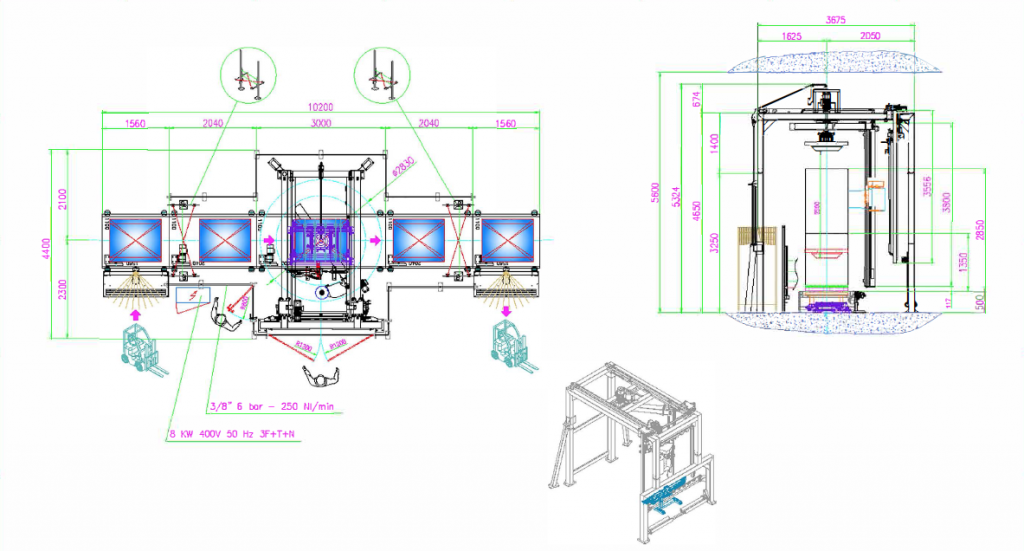

What we can see in the image is not just any machine, in automotive slang it is known as a “full equip”. It is a Revolution configured with accessories that elevate the load when packing, hold it to avoid tipping and cover it from the top. In addition, it also helps to save on film with a state-of-the-art electric pre-stretching carriage. Efficiency, economy and a reduction of the carbon footprint all in one. In this special situation, wrapping lightweight packages has special features.

The Revolution for wrapping lightweight packages

Talking about the Revolution is not just talking about a machine, but about a global project that, in this specific case, includes a complete line with motorized rollers and specific spaces for the entry of the load and its exit once packed. As we told you before, this is work carried out solely and exclusively for the client. Let’s see what this Revolution can do:

Elevador de carga: este accesorio permite que la envolvedora envuelva el producto hasta cubrir toda la superficie del pallet, lo que permite conseguir más estabilidad y protección durante su transporte. En cargas ligeras, como es el caso, es un accesorio imprescindible.

- Loading elevator: this accessory allows the wrapper to wrap the product so that the entire surface of the pallet is covered, which allows for more stability and protection during transport. In light loads, such as this, it is an essential accessory.

- Gripper: The gripper is a key piece, so that loads, especially those that weigh less, are well secured during packing. This simple process not only gives the load balance and security, but also ensures packaging which will stand any type of transport.

- Top cover: the top cover seals the packaging of the product even more. This process covers the upper part of the pallet with a layer of film to completely cover the load, preventing damage to the upper part and from water entering.

- Electric pre-stretch carriage: This pre-stretch carriage is at the forefront of packaging, and is the perfect culmination for the Revolution where pallets do not exceed 100kg. The electric PS carriage can work with much lower micron ratings than before, which directly impacts the carbon footprint, and also the customer’s economy. Less film means less waste and less expense, a win-win for any warehouse that thinks beyond mere production.

Our aim is yours

At Atlanta Stretch, it is clear to us that every company or client needs a customised solution. As you can see, this is one of our latest success stories. Are you interested in a project? Call or contact us and we will start to design something unique for you. Shall we start? Would you like to get to know the Revolution better? check out the technical specifications here.

Would you like to get in touch with us? info@atlanta-iberica.com

Español

Español Français

Français